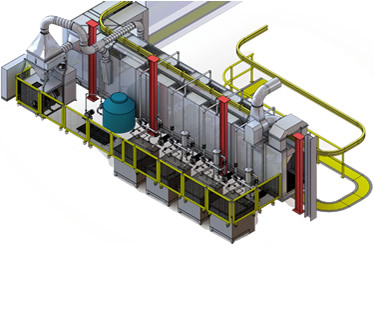

WASHERS

One Step Pretreatment Tunnel TTA1

This equip is built with panels IN STAINLESS STEEL PLATE. It has side doors for easy inspection of the tunnel. It is supported at the top by Structural Profile goals in preventing the tunnel walls lose their alignments, so it has double trap vapors to prevent environmental pollution.

What's Plaforization?

The plaforization is a treatment that cleans, degreases, Phosphate metal seals in one step. The workpiece is treated by dipping or spraying for one minute and does not require rinsing. Throughout the treatment, the metal surface is covered with both the phosphate as a polymer stamp simultaneously.

The main features of this product are:

• The treatment solution does not require to be changed.

• Provides corrosion protection to the parts.

• Opera at room temperature.

• Various metals can be treated simultaneously.

• Friendly to the environment and the operator.

• Low cost of investment and operation.

• No effluent or solid waste creates.

• It is easy to operate.

Continuous Burn-Off Washer

This Continuous Burn-Off Washer accompanies the Continuous Burn-Off Oven in removing baked-on paint from racks and hooks.

Paint turns to ash in the oven and then enters the washer, where water rinses off paint ash and cools the racks and hooks. An industrial cartridge filter removes excess ash from the water stream.

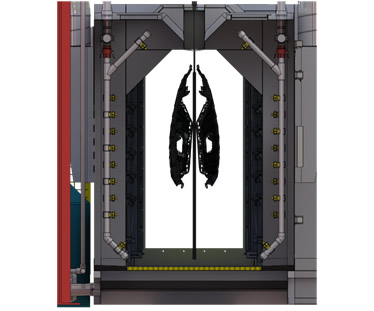

Batch Burn-Off Washer

The Batch Burn-Off Washer is designed for secondary cleanup of burned off racks, hooks, fixtures and parts. Overhead and corner nozzles spray water on the part, flushing the loose paint ash from the surface.

This ash travels to the filtration area, where it is collected for manual removal. Overhead roll-up doors, located at the front and rear of the booth, allow the operator to access the load for manual detailing and final removal.

Pre-Treatment Washer

Continuous Burn-Off Washer

Batch Burn-Off Washer

OIG ©2019 - Web Design and Development by